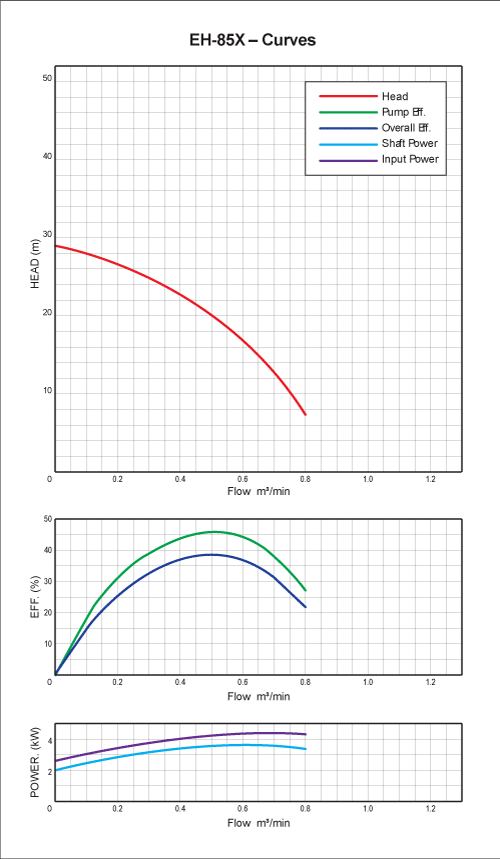

RATED DUTY: 200 L/min @ 25m

Explosion-proof and flame-proof submersible underground pump.

The smallest pump in the Explosion-proof | Flame-proof Submersible Pump series, the

EH-85X is a high quality low head portable pump outperforming the competition both in discharge head capacity and flow rate.

This low pressure pump excels in swilly and general fluid transfer workload duties operating safely in hazardous environments containing explosive gases and vapours with IECEx Certification.

Designed and engineered for high performance efficiencies with less down-time, this pump features a double upper lipseal and lower mechanical seal protection, each lubricated within an oil chamber independent to the fluid being pumped.

The mechanical seals are not exposed to the harsh pumping environment and abrasion which provides a much longer seal and overall pump life.

Easy care and maintenance design of the wet end makes it possible for very fast maintenance and repairs of the impeller and suction cover even underground in most cases.

- Power cable specifically designed for submersible applications withstanding temperatures of up to 90ºC.

- Cable entry engineered to reduce likelihood of conductor damage, cables fitted into junction chamber cover via a certified cable gland.

- Lifting Rings: Oversized built-in AISI-304 dual lifting rings for safe handling.

- Minimum bearing life L10 30,000 hours standard for EMQY and EMJY series, bearings packed with lithium grease for high temperature usage.

- Motor housing constructed from rugged cast iron ASTM type 448, Class 35.

- Motor Construction: An air filled, three phase squirrel cage induction motor for submersible or dry pit duty, specially treated stator windings with a treated non-hygroscopic insulation system. Direct online for up to 10HP and Star-Delta winding for 15HP and above are standard.

- Motor Temperature Control: Two automatic-resetting bimetallic thermostats connected in series for limiting motor temperature are embedded in the motor windings.

- Rotor is cast and dynamically balanced.

- Shaft is AISI-420 stainless steel oversized for maximum strength and life.

- Oil chamber lubricates and cools the shaft seals, functions as a buffer preventing water penetration into the motor.

- Leakage Detector: A single-electrode or dual-electrode leakage detectors are installed in the oil chamber for sensing water penetration.

- Shaft Seals: Double mechanical seals prevent water from penetrating into the oil chamber and the motor housing.

- Rated explosion-proof and flame-proof certification for underground mine dewatering.

- Hardware: All external hardware is made of AISI-304 stainless steel.